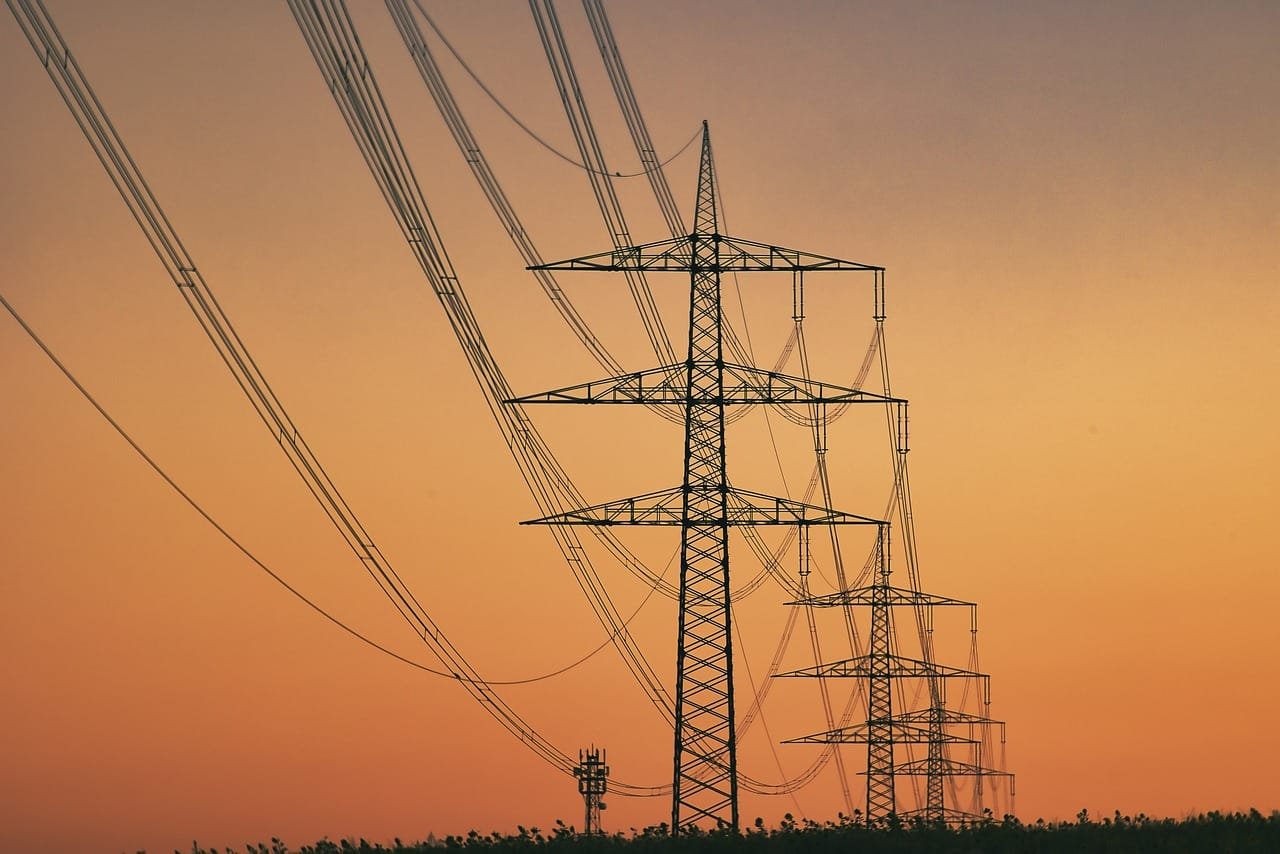

Power transmission tower, also known as transmission tower or power iron tower, is an extremely crucial infrastructure in the power transmission system and plays an irreplaceable role in ensuring the safe and efficient transmission of electric energy. The following is a detailed introduction for you:

I. Types and characteristics

(1) Angle steel tower

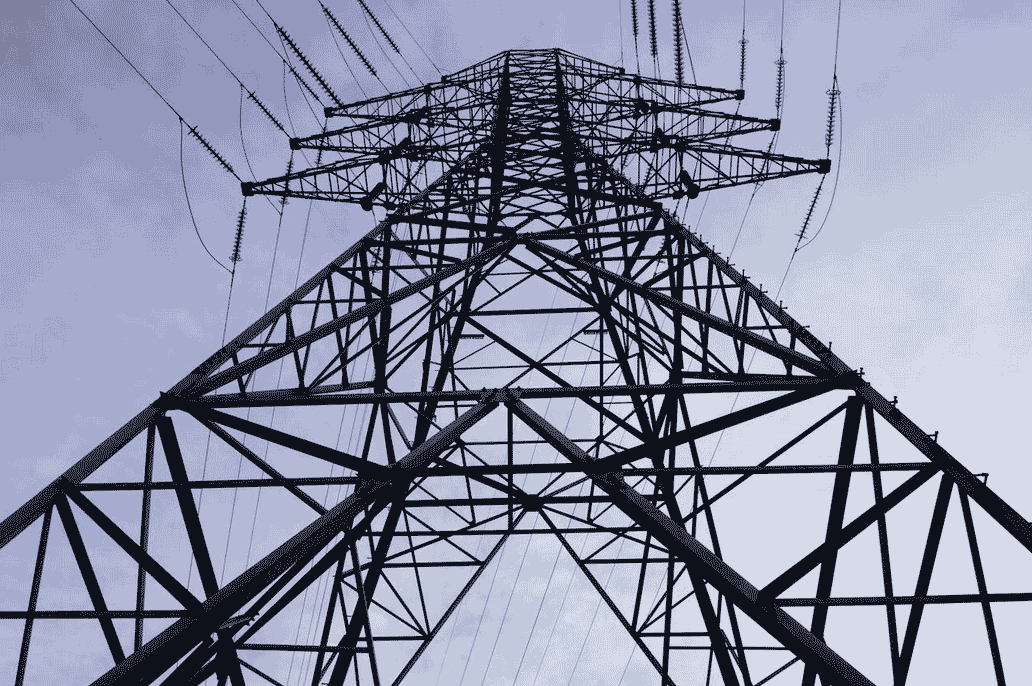

Structural characteristics: Mainly assembled by angle steel through bolt connection or welding. The overall structure presents a relatively regular space truss structure. It has various shapes, such as cat-head tower, cup tower, and dry-character tower. Each shape is suitable for different transmission line scenarios and voltage level requirements.

It has good stability and bearing capacity and can withstand large self-weight loads, conductor tension, wind loads, icing loads and other external forces. It can reliably support transmission lines in complex natural environments and various working conditions.

Application scenarios: Widely used in high-voltage and ultra-high-voltage transmission lines, especially in areas with relatively open terrain and relatively conventional meteorological conditions, such as plains and hilly areas. It is often used as the main type of transmission line tower for long-distance transmission lines.

(2) Steel tube tower

Structural characteristics: Uses steel tubes as the main construction material. The shape is mostly in the form of a single tube or a combination of multiple tubes. The appearance is relatively simple and smooth. Compared with angle steel towers, steel tube towers have a relatively small wind resistance coefficient and have certain advantages in withstanding wind loads. Moreover, their structure is compact and can effectively save steel consumption.

The node connection method of steel tube towers is relatively complex. Generally, processes such as intersecting welding are used. The welding technology and quality requirements are relatively high. However, the overall structure has excellent integrity and stability.

Application scenarios: It is more used in urban and suburban areas. Due to the relatively tight land resources and relatively high landscape requirements in these areas, the characteristics of small floor area and beautiful appearance of steel tube towers make them more in line with environmental requirements. At the same time, it is also suitable for the construction of transmission lines in some areas with strong winds.

(3) Guyed tower

Structural characteristics: Relies on guy wires such as steel strands to enhance the stability of the tower body. The tower body itself is usually made of materials such as angle steel or steel tube, and the structure is relatively lightweight. The guy wires are fixed at a certain angle to the ground and can share the horizontal tension borne by the tower body, making the tower more stable when bearing loads such as conductor tension.

However, guyed towers require a larger surrounding space to arrange guy wires, and their guy wires are easily affected by external environmental factors. For example, they are relatively more likely to be damaged by human activities or natural disasters.

Application scenarios: It is often used in special terrain areas with strict restrictions on tower body self-weight, such as mountainous areas, swamps, etc. Or it will also be used in some temporary transmission line construction scenarios. Because of its relatively low construction cost and relatively convenient construction.

II. Functions

(1) Supporting transmission lines

The core function of power transmission towers is to provide stable support for transmission conductors, lightning conductors, etc., ensuring that they maintain a reasonable height and spacing in the air, avoiding contact between conductors and the ground or other obstacles, ensuring that electric energy can be safely and smoothly transmitted along the predetermined line, and preventing power accidents such as short circuits and groundings caused by line sagging and swinging.

(2) Ensuring electrical safety distances

During the operation of transmission lines, specific electrical safety distances need to be maintained between different phase conductors and between conductors and the ground and surrounding objects to prevent electrical breakdown, flashover and other phenomena, thereby avoiding power outages and safety threats to surrounding people and facilities. Power transmission towers can ensure that all parts of transmission lines maintain standard-compliant safety distances through accurate design and reasonable height and position layout, creating a safe transmission environment.

(3) Adapting to different terrains and environments

Under various complex topographical and geomorphological conditions, such as high mountains and ridges, rivers, lakes and seas, and vast plains, power transmission towers can be constructed according to local conditions. Through reasonable selection and special design considerations, they can be firmly rooted in land with different geological conditions, overcome unfavorable factors such as terrain undulations, strong winds, and icing, and ensure that transmission lines can cross different regions and realize large-scale power transmission.

III. Design and construction points

(1) Structural design

Load calculation: Multiple load factors need to be comprehensively considered, including conductor self-weight, tension, wind load (calculated according to wind speed and direction data in different regions and the wind resistance coefficient of the tower body, etc.), icing load (considering possible icing thickness, ice density, etc.), and earthquake load (determined according to local seismic fortification intensity and other conditions). Accurately calculate the forces that the transmission tower needs to bear under different working conditions to provide a basis for subsequent structural selection and component design.

Structural selection and optimization: According to factors such as voltage level, transmission capacity, path terrain and surrounding environment of the transmission line, select the appropriate type of transmission tower and optimize its structure. Ensure that under the premise of meeting strength, stiffness and stability requirements, save materials and reduce costs as much as possible, and improve the wind resistance and seismic resistance of the structure.

(2) Material selection

Steel selection: Generally, steels with high strength, good toughness and good weldability are selected. Steels such as Q235 steel and Q345 steel are relatively commonly used. For transmission towers in some special environments, such as environments prone to corrosion in coastal areas, special steels with stronger corrosion resistance or special anti-corrosion treatment for steels will be selected.

Anti-corrosion materials: In order to deal with the corrosion problem that is easy to occur due to long-term exposure to the outdoor environment, anti-corrosion materials such as hot-dip galvanizing, epoxy zinc-rich primer, and acrylic polyurethane topcoat will be used in combination. Through pretreatment of the steel surface and multi-layer coating processes, the anti-corrosion ability of the transmission tower is enhanced and its service life is prolonged.

(3) Construction

Foundation construction: The foundation is the key to the stability of the transmission tower. Appropriate foundation forms should be adopted according to different geological conditions (such as soft soil foundation, rock foundation, etc.). Common ones include independent foundation, pile foundation, etc. During the construction process, key links such as foundation size, burial depth, and concrete pouring quality need to be strictly controlled to ensure that the foundation can provide sufficient bearing capacity and anti-overturning ability for the transmission tower.

Component installation: According to the design requirements, accurately transport the prefabricated tower components to the construction site for assembly. Whether it is bolt connection or welding operation, relevant construction specifications and quality standards must be strictly followed to ensure that the components are firmly connected and in the correct position, and ensure the structural integrity and stability of the entire transmission tower.

IV. Maintenance and management

(1) Regular inspections

Arrange professional personnel to conduct on-site inspections of power transmission towers regularly. The inspection contents include whether the tower body structure is deformed, corroded, or whether bolts are loose. Whether the conductor connection is firm and whether there is any broken strand. Whether insulators are damaged or contaminated. Once abnormalities are found, records should be made in time and corresponding repair and replacement measures should be taken.

(2) Anti-corrosion maintenance

Since transmission towers are subject to natural erosion such as wind, rain, sun exposure and rain for a long time, corrosion is prone to occur. Therefore, regular anti-corrosion maintenance work is needed, such as repainting anti-corrosion paint and checking the integrity of the hot-dip galvanized layer. Deal with the found corrosion parts in time to ensure good anti-corrosion performance of the transmission tower and prolong its service life.

(3) Condition monitoring and assessment

With the help of advanced monitoring technologies and equipment, such as using unmanned aerial vehicle inspections and online monitoring sensors (monitoring parameters such as tower body inclination, stress changes, environmental temperature and humidity), etc., to master the operating status of transmission towers in real time. Through the analysis and assessment of monitoring data, potential safety hazards can be found in time, and corresponding maintenance and reinforcement plans can be formulated in advance to ensure the long-term stable and reliable operation of power transmission towers.

As the “backbone” of power transmission, power transmission towers play a crucial role in ensuring the normal operation of the power system and meeting social electricity demand. Every link from design, construction to maintenance and management is related to the safety and stability of power transmission.

What are the characteristics of the design and use of power transmission towers under different voltage levels?

How to select the type of power transmission tower suitable for specific terrain and environmental conditions?

Introduce the basic types and characteristics of power transmission towers.

Sale!

Power tower

Power transmission tower

Original price was: $3,000.00.$2,900.00Current price is: $2,900.00.

& Free ShippingPower transmission line towers, also known as transmission towers or power pylons, are extremely crucial infrastructure in the power transmission system and play an irreplaceable role in ensuring the safe and efficient transmission of electric energy. The following is a detailed introduction for you.

| Weight | 1000 kg |

|---|

Reviews

There are no reviews yet.